We Mill Logs into Lumber on Your Site

Instead of bringing your logs to US, we bring the saw mill to YOU, mill your logs and stack the lumber on your site. For over 10 years, we’ve been the preferred mobile saw mill for the NC Piedmont, Western NC, Upstate SC and Eastern TN areas.

Debris Hauling & Cleanup

Clearing & Site Prep

Mobile Saw Milling

Project Consulting & Management

We've been featured in:

CHRIS CARROLL | Owner Operator

Hi! I’m Chris Carroll

As a sawyer who’s earned Woodmizer’s Million Boardfoot designation, you can trust me to mill your lumber correctly with the least amount of waste.

My 28+ years experience in the home construction, woodworking and sawmill industries gives me the unique expertise to educate landowners how to best utilize trees from their property for woodworking projects and building materials. Having worked with landowners in Charlotte, Upstate SC and Western NC, I am familiar with local building codes and what’s required to use the timber from your property in your home.

F.A.Q.

Frequently Asked Questions

How Much Do You Charge?

For mobile saw milling, we work on a half day and full day basis.

No two jobs are the same and to give an accurate quote, we will need to talk to you. There are many factors involved such as how long it takes to get to your jobsite, how many logs you have and what size they are, if you require a skid steer or special equipment, etc. Please call us for an accurate quote.

What Lengths Should I Have the Tree Guy Cut My Logs To?

To get the best quality and quantity from your trees, it's essential to have them cut into proper lengths. You may have a specific project in mind that requires a particular length of board. If not, we suggest cutting your logs in 2 foot increments, starting with 8 feet 6 inches (10'6", 12'6" etc). The extra six inches allows for trimming the ends when it's used for building furniture, siding etc. Due to the time involved, we typically do not mill logs shorter than 6'.

Is It Cheaper to Mill or Buy Lumber?

We understand our clients respect the environment and appreciate using trees they have rather than paying to have them hauled to a landfill. We also understand most clients are on a budget and try to balance the two.

This FAQ requires an in-depth response, which you can find on this blog post.

How do I prep my logs for milling?

To get the most lumber, it is best to saw as quickly as the trees are cut. If this is not possible, there are some steps you can take to preserve the tree for milling. These steps should be taken if more than a month will pass between the time it's on the ground and the time you have it sawed. First, raise the logs off the ground at least 4-6 inches and keep the grass around them trimmed. This discourages insects. Second, to avoid shrinking and cracking, seal the ends of the logs soon after cutting. You will want to use a wax, a heavy coat of paint or a product like Anchor Seal. Simply "paint" the ends of the logs to seal the end grain. If you are just now reading this and did not seal your ends, no worries! Most likely you'll only end up with shorter lumber.

Also, time is money so the more time we spend cleaning your logs of mud, nails and other debris, the less time we spend milling and the less lumber you get for your price. It is in your best interest to either keep your logs mud free when positioning them for milling. If they do get mud or debris on them, use a wire brush to remove any mud or debris on your logs.

I have a huge tree/log. How big of a tree can your mill handle?

We can mill logs up to 32" in diameter and 18 1/2 feet long.

Do you service my area?

Our primary service areas are Western NC, the Piedmont area of NC, Upstate SC and Eastern TN. We have completed jobs several hours away such as Charleston, SC. If you'd like to know about your specific area, please call us.

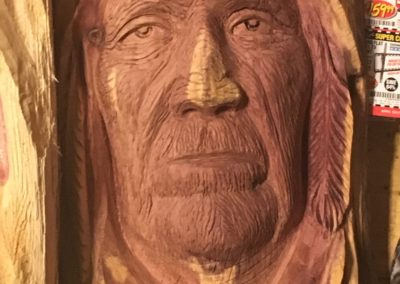

Gallery of Chris’ Carvings & Woodwork

Our Service Areas

We serve the entire southeastern United States but mostly North and South Carolina, including: Charlotte, Fort Mill, Hickory, Morganton, Greenville SC and Simpsonville SC. We do travel farther for larger jobs. Contact us for more info.

Office Hours

M-F: 9:00 am – 5:30 pm, Sat 8:30-Noon

Closed Sundays